Ceramic Wall Panel

Foamed Ceramic Wall Panel

- Product ID: TW Series Panel

- Planar Size: Standard 600x3000mm,900x3000mm,1200x3000mm & Customized

- Thickness: Standard 80mm,100mm,120mm & Customized Service Available .

- Materials: Foamed Ceramic

- Application Area: Private House, Office Building, Residence, Public Building

- INQUIRY

Foamed Ceramic Wall Panel is the key product of TSTC Building Materials , because of its independent airtight pore structure which is light and airtight, also because it has been calcined more than 1000℃ ( The value we adopt is 1200℃ ), make it possess the excellent features like sound insulation, heat preservation, acid &alkali resistance, corrosion resistance, excellent performance and could be durable for a much longer time compared with the traditional wall panels. Based on these, our foamed ceramic wall panel are highly favored by lots of office buildings, shopping malls, hospitals, high level residences and other types of buildings .

Advantages Of TSTC Ceramic Wall Panel

1. Lightweight. Around 10% construction materials could be saved by using TSTC wall panel compared with traditional solid walls, and lots of construction loads could be reduced.

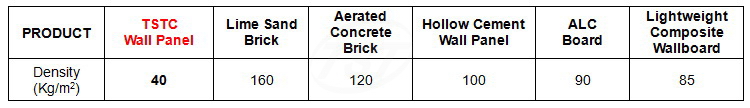

To TSTC ceramic wall panel , take thickness of 100mm for example , the areal density is only about 40Kg/m² (about 400Kg/m³) , that means, with the same conditions, the weight of TSTC Wall Panel is only 1/4 of Lime Sand Brick , 1/3 of Aerated Concrete Brick , about 1/2 of ALC Board and Hollow cement wall Panel , it’s almost the lightest wall panel for the buildings .

2. Thinner . TSTC Wall Panel is much more thinner compared with other similar products like Lime Sand Brick , Aerated Concrete Brick, Hollow cement wall panel , or ALC Board .

On the other hand, it indeed realizes the standardized thin plastering, the wall panel could be filling mastic directly without plastering, finally it could increase at least 3-5% actual usable area for the End Users.

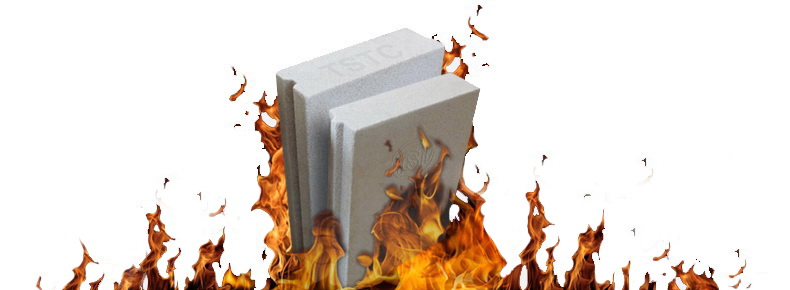

3. Class A1 Fire-resistant . TSTC ceramic wall panel overcomes the fatal weakness of inflammability of organic materials which fills the gaps of the inorganic insulation fireproof building materials in building material industry. Its combustion performance is A1 level and has very excellent fire resistant properties as it is produced under high temperature roasting (1150 ºC to 1200 ºC).

4. Better Sound Proof . The sound proof of TSTC Wall Panel could reach more than 50 dB, could effectively prevent the impact of noise, and bring you a quiet and comfortable environment .

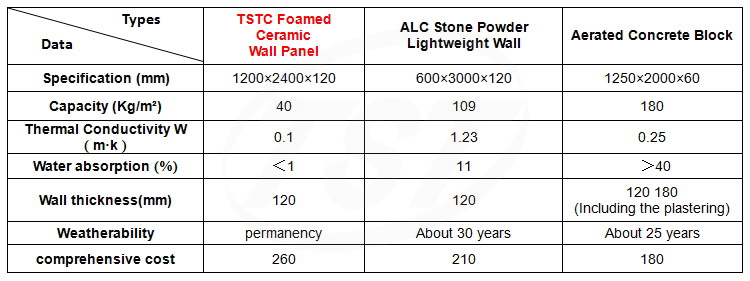

5. Better Thermal Insulation Performance. The coefficient of thermal conductivity of TSTC Wall Panel is less than 0.1 W/mk, with better heat insulation as well as better energy-saving.

With the same conditions, the coefficient of thermal conductivity of Autoclaved Aerated Concrete Block is about 0.25 W/mk, lime sand brick is about 0.8 W/mk. You can see that TSTC Wall Panel is an excellent thermal insulation material, which can effectively prevent the exchange of indoor and outdoor temperature, ensure the constant of indoor temperature, and finally to avoid the economic loss caused by energy loss.

6. Environment-friendly. High temperature firing products, green nontoxic and reusable .

7. Low Water Absorption .TSTC wall panel almost 100% cell closed, which make the panels have very low water absorption, the real water absorption <1%, with the same situation, the steamaeratedconcretebrick is about 40%, the lime sand brick is about 15% .

8. Higher Hanging Force. TSTC ceramic wall panel possess the higher hanging force, could bear various hangers of indoor or outdoor.

9. Healthy. TSTC ceramic wall panel has the features like anti-microbial and mould proof, which could help people to avoid the damage of health.

10. Anti-crack. Sintering product with extreme low shrinkage value and effective anti-crack.

11. Maintenance free. TSTC ceramic wall panel is with extreme low moisture content and water absorption and has a long-acting and stable performance.

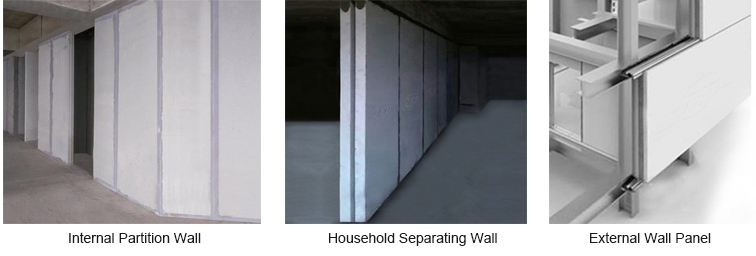

TSTC ceramic wall panel were widely used as Internal Partition Wall, Household Separating Wall and External Wall Panel.

Weight Comparision With Other Construction Blocks

The average weight of TSTC ceramic wall panel is 40kg /m² ( areal density ), which is the lightest solid wall material in the world up to now, only 1/3 of the weight of block wall and 1/2 of the weight of cement hollow wall panel. It has lightweight performance, but the compressive strength can reach 6-8 Mpa, which is much higher than other materials, so it is absolutely an ideal wall material.

Performance Comparison Between TSTC Ceramic Wall Panel and Traditional Wall

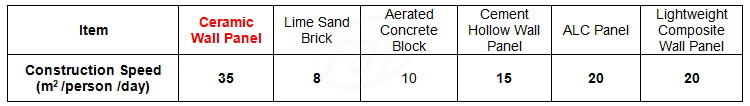

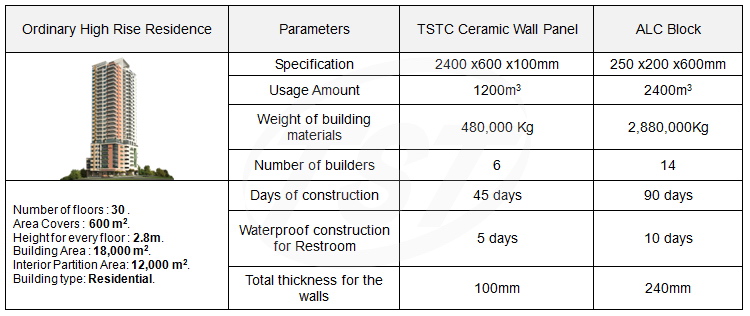

Comparison of Construction Speed Between Ceramic Wall Panel and other Construction Speed of TSTC Wall Panels

TSTC foamed ceramic wall panel has the features of light weight, large size, free leveling, thin plastering, no shrinkage and crack resistance. It realizes the standardized construction and greatly improves the efficiency of stonework. The construction speed is 2 times of the traditional wall panel and 5 times of the traditional block. It can shorten the period of stonework, save a lot of labor cost and improve economic benefit .

EXAMPLE - Comparison of Building Materials for Residence

Value Added Calculation.

1. Flatness . TSTC foamed ceramic wall panel possess the high flatness, no need to plastering, could save about 24,000m2 of plastering area.

2. Weight . TSTC foamed ceramic wall panel is much more lighter, which could reduce the weight for about 2,400,000 Kg for the whole building .

3. Usage Area . TSTC foamed ceramic wall panel is much more thinner, could save at least 1,680m2 usage area for the whole building .

4. Number of Builders . To use TSTC foamed ceramic wall panel, 8 construction people could be saved .

5. Construction Period . To use TSTC foamed ceramic wall panel, about 45 days could be saved for the construction period .

6. Maintenance Free . TSTC foamed ceramic wall panel is produced under the high temperature roasting (1150 ºC ~ 1200 ºC), much more stable, anti-crack, low water absorption, no need to maintenance, which means the big money for the subsequent maintenance could be saved .

Cost Saving Calculation ( EXAMPLE - Standards in China).

1. Cost of Plastering . 15RMB / m2, Total 15 x24,000= 360,000 RMB. (About USD 56,000 ).

2. Labor Cost . About 200 RMB /day in China. 8 x200 x50 = 80,000 RMB. (About USD 12,500 ).

3. Added Usage Area. Take 8,000RMB/m2 for example (In some cities, the price maybe 3 or 5 times), 8,000 x1,680=13,440,000 RMB. (About USD 2,100,000),

4. Structural Cost . Weight Reduced for the whole building is about 2,400,000 Kg , which also greatly reduces the load of the building as well as the Structural Cost.

Categories

News

Contact Us

Contact: TSTC Building Materials

Phone: +86 15042736579

Tel: +86 15042736579

E-mail: service@tstcbm.com

Add: Shentong Road, Lagu Industrial Park, Fushun City, Liaoning Province , China .