Industry News

Advantages, Limitations and Applications for Foamed Ceramic Wall Panel

Foamed ceramic wall panels, an innovative building material, are manufactured by high-temperature roasting (∼1200°C) of industrial wastes like glass/ceramic fragments, fly ash, and coal gangue to form a lightweight, porous structure. Below is a detailed analysis of their characteristics and uses.

Advantages

▪ Superior Thermal Insulation

Low thermal conductivity (0.048–0.12 W/(m·K) due to >90% closed-cell porosity, significantly reducing building energy consumption (e.g., 22% lower HVAC load in tests).

▪ Fire Safety

Classified as A1-grade non-combustible material, maintaining structural stability at 1200°C. Proven effective in fire barriers, delaying flame spread for >2 hours in high-rise fires.

▪ Lightweight & High Strength

Density (380–500 kg/m³) is 1/3–1/4 of traditional stone, yet compressive strength reaches 5–15 MPa. Reduces building load by ∼18% and enhances seismic resilience.

▪ Durability and Weather Resistance

▪ Resists corrosion, UV radiation, and freeze-thaw cycles. Low water absorption (≤1.2%) prevents moisture damage, ideal for humid areas like bathrooms. Lifespan exceeds 50 years, matching building longevity.

▪ Eco-Friendliness

Incorporates 30–50% industrial waste (e.g., coal gangue, tailings). Fully recyclable into lightweight aggregates, reducing mining waste by 800 tons per 10,000 m² application.

Limitations /Disadvantages

▪ High Cost

Production expenses are 2–3× higher than EPS foam (e.g., $1,000–2,000/m³ vs. $300–500/m³), limiting widespread adoption.

▪ Installation Complexity

Requires precise venting pipelines to prevent hollowing ("drumming") and specialized adhesives for secure bonding.

▪ Surface Vulnerability

Prolonged UV exposure may cause micro-cracks; surface protection (e.g., coatings) is recommended.

▪ Energy-Intensive Production

▪ High-temperature firing increases energy use, though lower than traditional ceramics by 200°C.

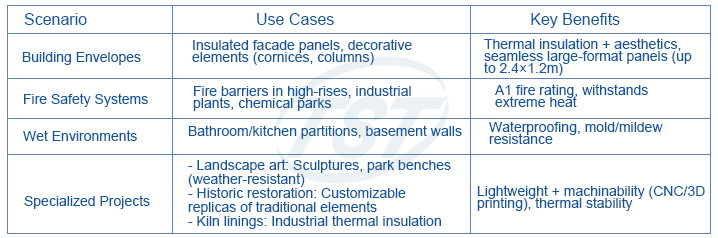

Application Scenarios

Conclusion

Foamed ceramic panels excel in scenarios demanding fire safety, longevity, and thermal efficiency-particularly high-rises, wet areas, and cultural projects. While costs remain a barrier, standards like T/CECS 877-2021 and T/SXCAS 025-2024 are accelerating adoption. Advances in waste utilization (e.g., higher fly ash ratios) may further enhance sustainability, positioning this material as a cornerstone of green construction.

Categories

News

Contact Us

Contact: TSTC Building Materials

Phone: +86 15042736579

Tel: +86 15042736579

E-mail: service@tstcbm.com

Add: Shentong Road, Lagu Industrial Park, Fushun City, Liaoning Province , China .