Ceramic Wall Panel

Ceramic Composite Panel

- Product ID: TW-CP100

- Planar Size: Standard 600x2400mm,600x3000mm & Customized

- Thickness: Standard 100mm, 150mm, 180mm & Customized Service Available .

- Materials: Foamed Ceramic, Polyphenyl Granule, Cement

- Application Area: Office Building, Residence, Hotel, Public Building

- INQUIRY

TSTC Ceramic Composite Panel is made of lightweight ceramic wall panel , light core material, steel mesh and other materials . Because of its excellent features like Class A1 Fire-resistant, better Sound Proof, better Thermal Insulation Performance, low Water Absorption, it was widely used as partition Wall, firewall, exterior wall.

The Advantages of TSTC Ceramic Composite Panel.

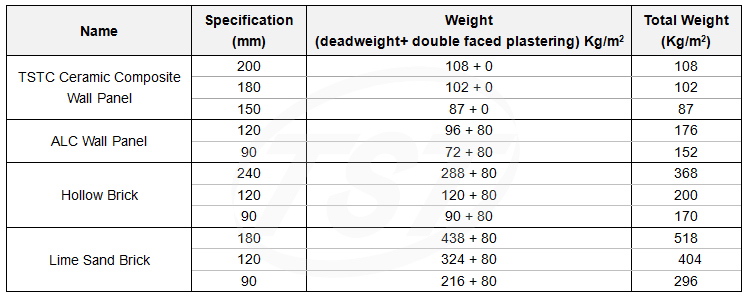

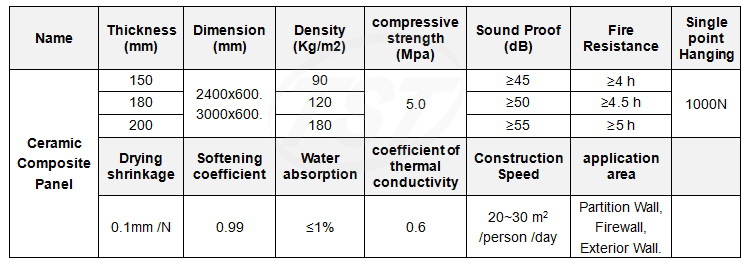

1. Lightweight. The density of foamed ceramic composite wall panel is less than 580kg/m3, which can realize the thin plastering or even 0 plastering. The weight per square meter is far lower than that of solid masonry wall with the same efficiency, which greatly reduces the load of the building.

2. Class A1 Fire-resistant . TSTC composite panel is produced under the high temperature roasting (1150 ºC ~ 1200 ºC),its combustion performance is A1 level , the fire resistance could reach to 5 hours .

3. Better Sound Proof .The sound proof of TSTC Composite Panel could reach more than 50 dB, could effectively prevent the impact of noise, and bring you a quiet and comfortable environment .

4. Better Thermal Insulation Performance. The coefficient of thermal conductivity of TSTC composite Panel is less than 0.1 W/mk, with the same conditions, the coefficient of thermal conductivity of Autoclaved Aerated Concrete Block is about 0.25 W/mk, lime sand brick is about 0.8 W/mk. Because of the better heat insulation as well as better energy-saving of TSTC composite Panel,it finally could avoid the economic loss caused by energy loss.

5. Environment-friendly. High temperature firing products, long duration and green nontoxic.

6. Low Water Absorption .The key part of TSTC composite panel is ceramic wall panel which almost 100% cell closed, make the panels have very low water absorption, the real water absorption <1%, with the same situation, the steamaeratedconcretebrick is about 40%, the lime sand brick is about 15% .

7. Easy-to-use. TSTC composite panel possess the higher hanging force, can be nailed and hung, the hanging force of single point could reach 1000N, brings the great convenience for the subsequent construction and decoration.

8. Healthy. Anti-microbial and mould proof, to help protect the damage of health.

9. Anti-crack. Sintering product with extreme low shrinkage value and effective anti-crack.

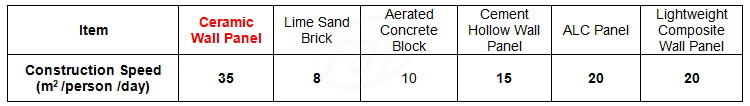

10. Faster Construction Speed. To TSTC composite panel, because of its larger dimension, light weight, free leveling, thin plastering,it realizes the standardized construction and greatly improves the construction speed,the construction speed is about 2 times of the traditional wall panel and 3 times of the traditional block,which greatly shorten the construction period as well as saved a lot of labor cost and improve economic benefit. To the traditional building block, the construction speed is about 10m²/person/day, and to TSTC composite panel is about 100m²/3 persons/day ( 33m²/person/day ), about 2 times faster, saved a lot labor cost .

The Parameters of TSTC Composite Panel

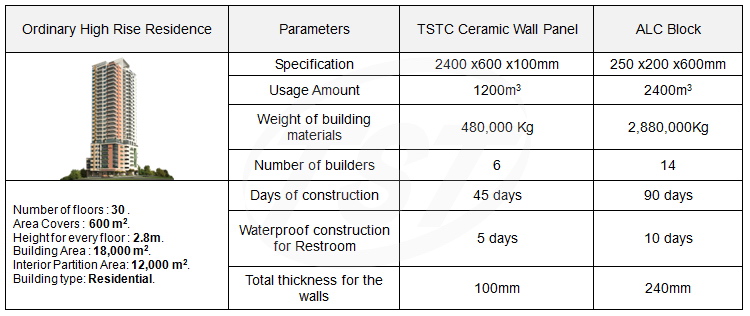

EXAMPLE - Comparison of Building Materials for Residence

Value Added Calculation.

1. Flatness . TSTC foamed ceramic wall panel possess the high flatness, no need to plastering, could save about 24,000m2 of plastering area.

2. Weight . TSTC foamed ceramic wall panel is much more lighter, which could reduce the weight for about 2,400,000 Kg for the whole building .

3. Usage Area . TSTC foamed ceramic wall panel is much more thinner, could save at least 1,680m2 usage area for the whole building .

4. Number of Builders . To use TSTC foamed ceramic wall panel, 8 construction people could be saved .

5. Construction Period . To use TSTC foamed ceramic wall panel, about 45 days could be saved for the construction period .

6. Maintenance Free . TSTC foamed ceramic wall panel is produced under the high temperature roasting (1150 ºC ~ 1200 ºC), much more stable, anti-crack, low water absorption, no need to maintenance, which means the big money for the subsequent maintenance could be saved .

Cost Saving Calculation ( EXAMPLE - Standards in China).

1. Cost of Plastering . 15RMB / m2, Total 15 x24,000= 360,000 RMB. (About USD 56,000 ).

2. Labor Cost . About 200 RMB /day in China. 8 x200 x50 = 80,000 RMB. (About USD 12,500 ).

3. Added Usage Area. Take 8,000RMB/m2 for example (In some cities, the price maybe 3 or 5 times), 8,000 x1,680=13,440,000 RMB. (About USD 2,100,000),

4. Structural Cost . Weight Reduced for the whole building is about 2,400,000 Kg , which also greatly reduces the load of the building as well as the Structural Cost.

Categories

News

Contact Us

Contact: TSTC Building Materials

Phone: +86 15042736579

Tel: +86 15042736579

E-mail: service@tstcbm.com

Add: Shentong Road, Lagu Industrial Park, Fushun City, Liaoning Province , China .